Temperature chambers are vital tools in many industries, enabling companies to test and simulate environmental conditions to ensure product quality and durability. Whether you’re in electronics, aerospace, pharmaceuticals, or any sector requiring precise environmental testing, understanding the capabilities and uses of temperature chambers is crucial. This comprehensive guide explores the functions, applications, and key considerations when selecting a temperature chamber for your needs.

What is a Temperature Chamber?

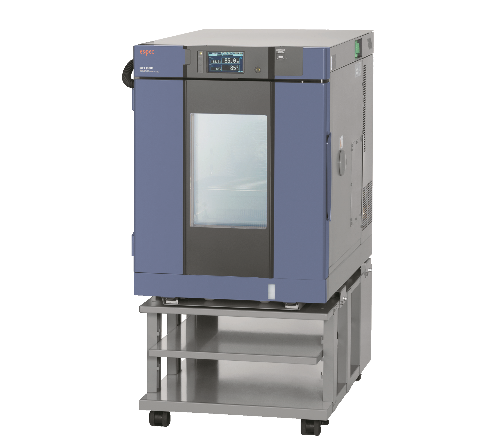

A temperature chamber, also known as a climatic or environmental chamber, is a controlled environment that can simulate temperature conditions ranging from extreme cold to extreme heat. These chambers are designed to test the effects of temperature fluctuations on materials, electronic devices, and other products to ensure they can withstand various environmental conditions.

Applications of Temperature Chambers:

Product Testing and Validation: Ensuring products can withstand harsh temperatures before they hit the market.

Research and Development: Facilitating the development of new products and materials under controlled temperature conditions.

Quality Control: Regular testing to maintain quality standards in manufacturing processes.

Stress Screening: Identifying product weaknesses early in the manufacturing stage.

Benefits of Using Temperature Chambers:

Reliability: Helps ensure that products are robust and durable under any temperature conditions.

Precision: Offers precise control over temperature settings to meet specific testing requirements.

Efficiency: Accelerates the testing process by quickly adjusting temperatures to desired levels.

Compliance: Assists in meeting various environmental standards and regulations set by industries.

Choosing the Right Temperature Chamber: Selecting an appropriate temperature chamber involves several key considerations:

Temperature Range: Consider the maximum and minimum temperature requirements based on the products you are testing.

Size and Capacity: Ensure the chamber is large enough to accommodate your samples but also suitable for your laboratory or testing facility space.

Control and Accuracy: Look for chambers with advanced control systems for accurate temperature regulation and ease of use.

Durability: Choose a chamber built to withstand the rigors of your testing frequency and environment.

Budget and Cost-Effectiveness: Balance your budget with the operational and maintenance costs of the chamber.

Conclusion: Temperature chambers are indispensable tools in ensuring that products meet the stringent requirements of safety and durability under varying temperatures. Whether for industrial use, research, or quality assurance, the right temperature chamber can provide significant insights into product behavior under extreme conditions and help in refining product designs. With this guide, you are equipped to make an informed decision on the best temperature chamber that suits your business needs, ensuring ongoing compliance and product excellence.