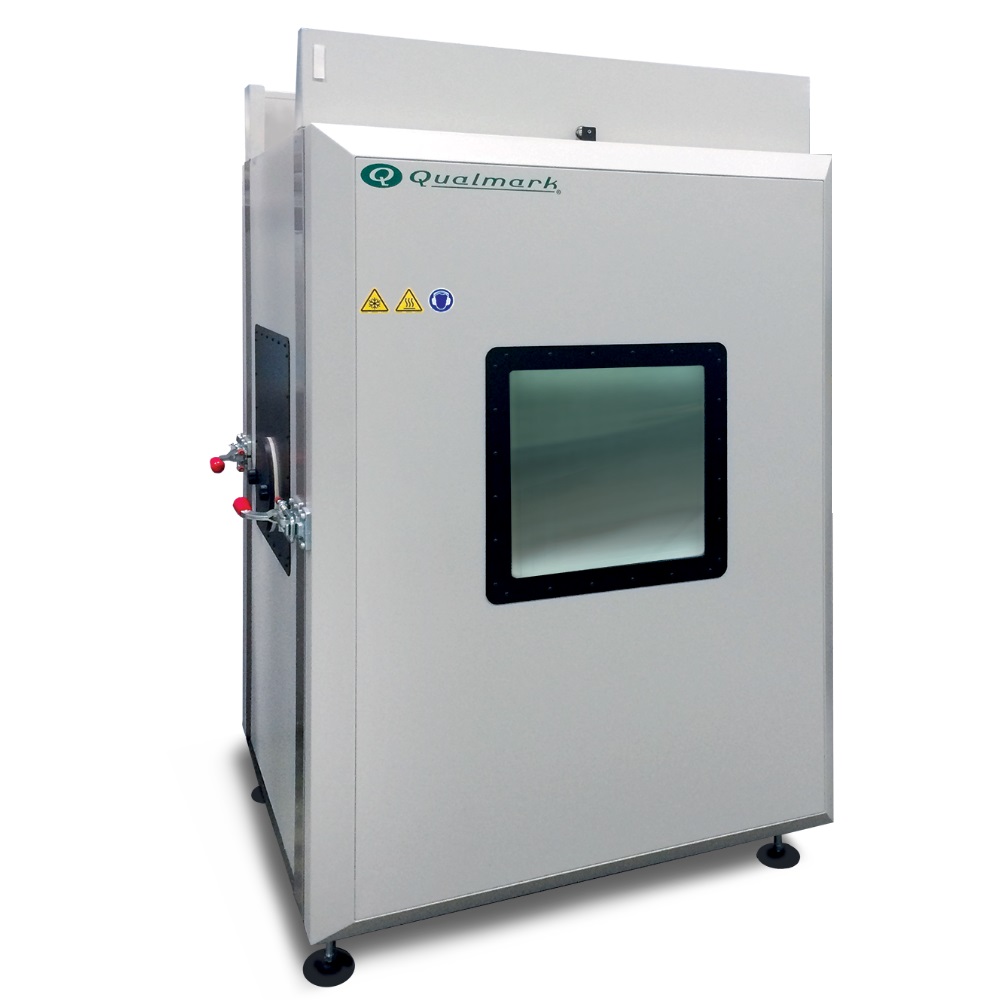

Qualmark HALT and HASS Chamber

Description:

HALT and HASS are unique reliability test methods for finding faults and weak spots in a product before they are discovered in the field. The HALT method is often used during the development phase of a product in order to quickly find any weak components at an early stage and so eventually realise a more robust product before it is put into production. The HAST method is applied after production in order to detect any defects that may have occurred before or during the production process.

Extreme thermal (temperature) and mechanical (vibration) stresses are applied to a product during a HALT or HASS test. Because the chambers are connected to nitrogen, temperatures of -100 °C tot +250 °C can be achieved and temperature changes of 100 °C can even take place. In combination with different vibration levels, this creates great stress on a product.

Hielkema Test Equipment has been delivering Qualmark HALT and HASS systems in the Benelux area for over 15 years. Qualmark is the leading brand for HALT and HASS chambers worldwide. Would you like to know more about the possibilities?

Technical specifications

- Test area:

Temperature range

Temperature rate of change:

TAcceleration:

- From 60 up to 5000 litre

-100°C to +200°C (+250°C option)

To 100°C/min possible

5 – 100 gRMS

Benefits:

- • Weak spots are quickly visible

• Reduces time-to-market

• Can reduce total warranty costs up to 50%

• Several models available

• Wide range of options and possibilities

Some options:

- • Additional cable ports or viewing windows

• Safety options, depending on application

• Datalogging up to 32 temperature en 12 vibration channels.

• Analyse (UUT) systems

• Status indicator

Industries:

- • Automotive

• Aerospace

• Communication

• Defense

• Electronics

• Energy

• Medical equipment

• Oil and gas

Applications:

- • HALT

• HASS