Climatic chambers, essential in a multitude of industries, offer a controlled environment to simulate a range of atmospheric conditions. These devices are crucial for testing the reliability and durability of products under various environmental stresses. Whether you’re involved in electronics, automotive, aerospace, or biotechnology, understanding climatic chambers can significantly impact your quality assurance processes. This guide provides an in-depth look at climatic chambers, their applications, and tips for selecting the ideal unit for your needs.

What are Climatic Chambers?

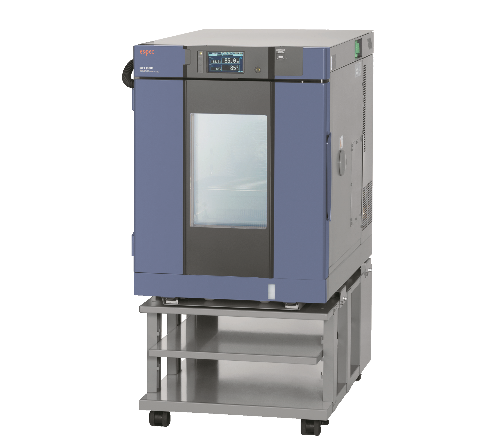

Climatic chambers, also known as environmental chambers, are specialized enclosures designed to replicate environmental conditions. They can adjust temperature, humidity, and other atmospheric parameters to precise levels, allowing researchers and engineers to observe how products and materials behave under different climatic scenarios.

Applications of Climatic Chambers:

- Product Testing and Development: Simulating different climates to test product endurance and operation.

- Research and Innovation: Providing researchers the environment to study environmental effects on materials and biological entities.

- Quality Assurance: Ensuring products meet environmental compliance and withstand intended use conditions.

- Life Testing: Accelerating aging processes to predict product lifespan under normal and extreme conditions.

Benefits of Climatic Chambers:

- Versatility: Suitable for a variety of industries and applications, from electronics to pharmaceuticals.

- Precision Control: Advanced technology to accurately simulate a wide range of environmental conditions.

- Consistency: Offers a consistent testing environment for reliable data and results.

- Compliance Support: Helps manufacturers meet strict regulatory standards by proving product robustness.

Choosing the Right Climatic Chamber: When selecting a climatic chamber, consider these essential factors:

- Range of Conditions: Determine the temperature, humidity, and other environmental parameters needed for your tests.

- Size and Capacity: Match the chamber size to your product dimensions and the scale of your testing operations.

- Control Systems: Opt for chambers with user-friendly interfaces and precise control mechanisms.

- Energy Efficiency: Consider energy consumption, as climatic chambers can be significant power users.

- Maintenance and Support: Ensure availability of excellent customer service and technical support for maintenance.

Conclusion: Climatic chambers are pivotal in ensuring that products can withstand the environmental conditions they will face in their lifetime. Whether enhancing product durability, conducting regulatory compliance testing, or performing research, the right climatic chamber is a valuable investment. By carefully evaluating your specific needs and the capabilities of different climatic chambers, you can choose a model that not only meets your requirements but also enhances your testing and development processes.