Battery testing refers to the process of evaluating and analyzing the performance, characteristics, and safety of batteries under various conditions. This testing is essential to ensure that batteries meet specific standards, function reliably, and perform as expected in various applications, ranging from consumer electronics to electric vehicles and renewable energy storage systems. Battery testing involves a variety of measurements, assessments, and experiments to gather data about a battery’s behavior and characteristics.

Here are some key aspects of battery testing:

1. Performance testing: this involves evaluating a battery’s capacity (the amount of energy it can store), energy efficiency (how effectively it converts stored energy into usable power), and discharge rates (how quickly it releases stored energy).

2. Cycle life testing: this assesses how many charge and discharge cycles a battery can undergo before its capacity significantly degrades. This is crucial for determining a battery’s lifespan.

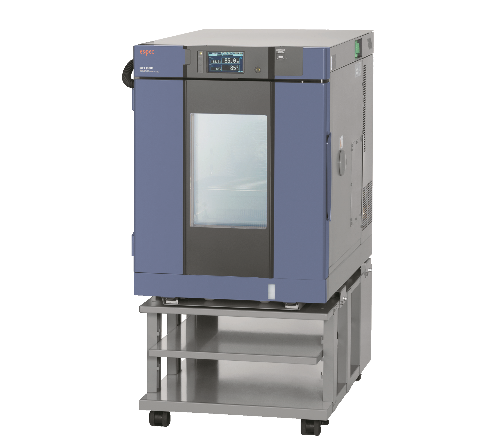

3. Environmental testing: batteries are often exposed to varying environmental conditions. Testing may involve subjecting batteries to extreme temperatures, humidity, and vibrations to assess how they perform and degrade under these conditions.

4. Safety testing: Safety is a critical concern, especially with lithium-ion batteries. Safety tests involve evaluating a battery’s thermal stability, sensitivity to impact, short-circuit behavior, and potential for thermal runaway (a condition where a battery overheats and possibly catches fire).

5. Aging and shelf life testing: this assesses how a battery’s performance changes over time, both during usage and when stored without being used. Shelf life testing determines how long a battery can be stored and still provide adequate performance.

6. Charge and discharge testing: this involves charging a battery to its full capacity and then discharging it under controlled conditions while measuring its voltage, current, and capacity. These tests help understand the battery’s efficiency and characteristics.

7. Rate capability testing: This measures a battery’s ability to deliver power quickly, which is important in applications like electric vehicles that require bursts of power for acceleration.

8. State of Charge (SOC) and State of Health (SOH) Monitoring: these tests assess the battery’s current capacity and overall health. Knowing the SOC and SOH is critical for determining a battery’s operational readiness.

9. Cycling and aging tests: Batteries are often cycled through different charge and discharge cycles to simulate real-world usage patterns and understand their long-term performance.

10. Emission and compatibility testing: Some battery chemistries might emit gases or substances when they degrade or fail. Emission and compatibility testing assesses potential hazards and interactions.

11. Electrical and thermal characterization: In-depth analysis of a battery’s electrical properties and thermal behavior provides insights into its performance and safety.

Battery testing is conducted in controlled environments using specialized testing equipment and protocols. The data collected from these tests informs manufacturers, researchers, and engineers about the battery’s capabilities, limitations, and potential improvements. This knowledge is critical for designing safe, efficient, and reliable battery-powered products across a wide range of industries.