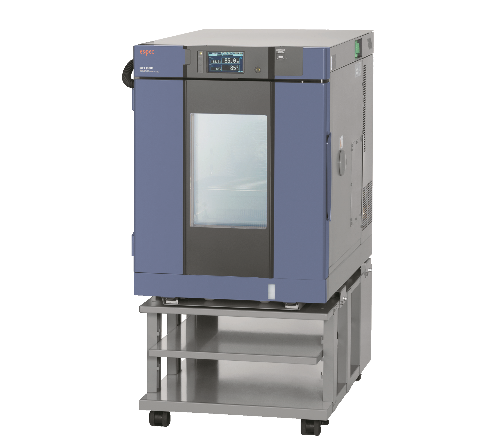

Espec Clean Room Ovens

Description:

Espec clean room ovens are mainly used for drying, hardening, curing or baking products in a clean environment. The clean room ovens feature a HEPA filter on the rear and have an internal laminar air circulation system, enabling a classification in class 100 to be achieved (even while warming up and cooling down). By default, the clean room oven has a digital controller that enables programs of up to 20 steps to be programmed. The clean room oven can also be fitted with several different advanced options for specific applications.

Technical specifications

- Capacity:

Temperature range:

Controller:

Shelves:

Power supply:

- 178, 380 or 678 litre

Ambient temp. to +200°C (+350°C)

Controller with LCD display

2 chrome-plated racks

230V / 400V

Benefits:

- • User friendly temperature controller

• Class 5 (class 100) cleanliness level

• Space-saving (vertical) installation

• Rapid heating times

• Reliable system

Some options:

- • Pre-filter (when installing outside cleanroom)

• Automatic adjustable air flap

• RS-485, GPIB or RS-232 interface

• Nitrogen connection

• O² controller

Industries:

- • Automotive

• Aerospace

• Chemistry

• Electronics

• Pharma / medical

• Semiconductor

• Solar panels

Applications:

- • Temperature tests

• Drying

• Curing

• Heat treatment

• Clean room

Related Products

-

ETERNAL SUN AND SOLLIANCE PARTNERS DEVELOP UNIQUE SOLAR TESTING SYSTEMA Dutch consortium, consisting of Eternal Sun, Hielkema Testequipment, Rera Solutions and Solliance partners ECN and TNO will develop a climate chamber with AAA-class accuracy simulated sunlight to simultaneously test performance and degradation of all types of solar cells and mini-modules. This unique combination is able to gather information which is at the moment unattainable. The equipment is expected to become commercially available in the first half of 2015.

ETERNAL SUN AND SOLLIANCE PARTNERS DEVELOP UNIQUE SOLAR TESTING SYSTEMA Dutch consortium, consisting of Eternal Sun, Hielkema Testequipment, Rera Solutions and Solliance partners ECN and TNO will develop a climate chamber with AAA-class accuracy simulated sunlight to simultaneously test performance and degradation of all types of solar cells and mini-modules. This unique combination is able to gather information which is at the moment unattainable. The equipment is expected to become commercially available in the first half of 2015. -

22ND ESPEC CHAMBER IN 22 YEARS OF SUCCESSFUL BUSINESSAbout 22 years ago (1993), Kees Revenberg, director of MASER Engineering BV, bought the first Espec climate test system from Peter Hielkema, former director of Hielkema Testequipment BV. Now, after 22 years of successful business cooperation, MASER Engineering BV has expanded their wide range of Espec test systems with yet another Espec test system

22ND ESPEC CHAMBER IN 22 YEARS OF SUCCESSFUL BUSINESSAbout 22 years ago (1993), Kees Revenberg, director of MASER Engineering BV, bought the first Espec climate test system from Peter Hielkema, former director of Hielkema Testequipment BV. Now, after 22 years of successful business cooperation, MASER Engineering BV has expanded their wide range of Espec test systems with yet another Espec test system -

CLIMATE CHAMBER WITH SOLAR SIMULATORAbout 4 years ago, Hielkema Testequipment, Eternal Sun & TNO developed a unique solar testing system for Solliance (High Tech Campus in Eindhoven). This system has been used very successfully to gain new insights into the degradation behavior of solar cells and mini-modules.

CLIMATE CHAMBER WITH SOLAR SIMULATORAbout 4 years ago, Hielkema Testequipment, Eternal Sun & TNO developed a unique solar testing system for Solliance (High Tech Campus in Eindhoven). This system has been used very successfully to gain new insights into the degradation behavior of solar cells and mini-modules. -

TÜV SÜD AND ESPEC PARTNERING FOR ELECTRIC VEHICLE BATTERY TESTING IN JAPAN.TÜV SÜD and ESPEC are currently expanding ESPEC's existing battery laboratory in Japan. By partnering up, the main aim is to offer a complete range of tests for drive batteries of electric cars. This will become the seventh lab of TÜV SÜD in the international network of battery labs.

TÜV SÜD AND ESPEC PARTNERING FOR ELECTRIC VEHICLE BATTERY TESTING IN JAPAN.TÜV SÜD and ESPEC are currently expanding ESPEC's existing battery laboratory in Japan. By partnering up, the main aim is to offer a complete range of tests for drive batteries of electric cars. This will become the seventh lab of TÜV SÜD in the international network of battery labs. -

TESTING OF LITHIUM-ION BATTERIES FOR ENERGY STORAGE SYSTEMS.The effective storage of energy is a development that receives a lot of attention from different sectors. The market for energy storage systems (including lithium-ion batteries) is currently growing explosively and offers many opportunities for various applications.

TESTING OF LITHIUM-ION BATTERIES FOR ENERGY STORAGE SYSTEMS.The effective storage of energy is a development that receives a lot of attention from different sectors. The market for energy storage systems (including lithium-ion batteries) is currently growing explosively and offers many opportunities for various applications. -

LV 124 AUTOMOTIVE TEST STANDARDSince 2010 the LV 124 has become the most important test standard for the automotive industry. The LV 124 includes several mechanical, climatic and life tests, such as the K-09 damp heat cyclic test, the K-15 condensation test and the L-03 temperature cycle life test.

LV 124 AUTOMOTIVE TEST STANDARDSince 2010 the LV 124 has become the most important test standard for the automotive industry. The LV 124 includes several mechanical, climatic and life tests, such as the K-09 damp heat cyclic test, the K-15 condensation test and the L-03 temperature cycle life test. -

Test facilityOur brand new test facility offers the possibility to see and test our products, but makes it also available for individual pre-compliance testing. In our test facility we have several climatic chambers, one salt spray chamber and 3 large walk-in climatic chambers available for testing.

Test facilityOur brand new test facility offers the possibility to see and test our products, but makes it also available for individual pre-compliance testing. In our test facility we have several climatic chambers, one salt spray chamber and 3 large walk-in climatic chambers available for testing. -

Thermal Shock ChamberUnveiling Thermal Shock Chambers: Mastering Extreme Testing In the realm of testing, where precision and realism intersect, thermal shock chambers take center stage. These specialized chambers subject materials and products to rapid and extreme temperature changes, simulating the abrupt transitions they might encounter in real-world scenarios. The process offers invaluable insights into how items respond to thermal stress, revealing weaknesses, and ensuring durability. How Thermal Shock Chambers Work: 1. Three-Zone Design:Thermal shock chambers typically consist of three zones: a hot zone, a cold zone, and a testing zone. The product is placed in the testing zone, while the other zones maintain hot and cold extremes. 2. Rapid Transition:The product undergoes rapid temperature shifts as it moves between the hot and cold zones. This emulates the sudden environmental changes that products might face in their lifecycle. 3.Precise Control Advanced control systems maintain precise temperature control in each zone, ensuring accuracy and repeatability of the testing process. Why Choose Hielkema Testequipment for Thermal Shock Testing: 1. Cutting-Edge Technology: Hielkema Testequipment's thermal shock chambers are equipped with state-of-the-art technology, ensuring accurate and consistent testing conditions for dependable results. 2. Customizable Solutions: We understand that each product is unique. Our thermal shock testing can be tailored to replicate specific temperature profiles, closely mimicking real-world conditions. 3.Expertise: With years of experience in testing and measurement, we bring expert guidance to your testing journey. Our team assists in choosing the right testing parameters and interpreting results. 4. Comprehensive Support:From installation to maintenance, our support is comprehensive. We're committed to ensuring your testing process is smooth and successful. 5. Industry Diversification: Hielkema Testequipment's thermal shock testing caters to a wide range of industries – from electronics and automotive to aerospace and beyond. 6. Reliability Assurance: Partnering with us instills confidence in your product's endurance. Our testing helps you identify vulnerabilities early, contributing to your products' long-term reliability. 7. Proven Track Record: Hielkema Testequipment is a trusted name in testing solutions, backed by a track record of delivering quality results and partnering with industries to achieve excellence. In a world where product reliability is non-negotiable, thermal shock testing is your compass. It directs you towards the path of resilience, helping you create products that thrive in the face of adversity. When you choose Hielkema Testequipment, you choose accuracy, customization, and expertise that propel your testing journey. Elevate your testing capabilities with us and ensure your products not only meet but exceed expectations. Our Thermal Shock Chambers

-

Temperature chamberTemperature chambers are vital tools in many industries, enabling companies to test and simulate environmental conditions to ensure product quality and durability. Whether you're in electronics, aerospace, pharmaceuticals, or any sector requiring precise environmental testing, understanding the capabilities and uses of temperature chambers is crucial. This comprehensive guide explores the functions, applications, and key considerations when selecting a temperature chamber for your needs. What is a Temperature Chamber? A temperature chamber, also known as a climatic or environmental chamber, is a controlled environment that can simulate temperature conditions ranging from extreme cold to extreme heat. These chambers are designed to test the effects of temperature fluctuations on materials, electronic devices, and other products to ensure they can withstand various environmental conditions. Applications of Temperature Chambers: Product Testing and Validation: Ensuring products can withstand harsh temperatures before they hit the market.Research and Development: Facilitating the development of new products and materials under controlled temperature conditions.Quality Control: Regular testing to maintain quality standards in manufacturing processes.Stress Screening: Identifying product weaknesses early in the manufacturing stage. Benefits of Using Temperature Chambers: Reliability: Helps ensure that products are robust and durable under any temperature conditions.Precision: Offers precise control over temperature settings to meet specific testing requirements.Efficiency: Accelerates the testing process by quickly adjusting temperatures to desired levels.Compliance: Assists in meeting various environmental standards and regulations set by industries. Choosing the Right Temperature Chamber: Selecting an appropriate temperature chamber involves several key considerations: Temperature Range: Consider the maximum and minimum temperature requirements based on the products you are testing.Size and Capacity: Ensure the chamber is large enough to accommodate your samples but also suitable for your laboratory or testing facility space.Control and Accuracy: Look for chambers with advanced control systems for accurate temperature regulation and ease of use.Durability: Choose a chamber built to withstand the rigors of your testing frequency and environment.Budget and Cost-Effectiveness: Balance your budget with the operational and maintenance costs of the chamber. Conclusion: Temperature chambers are indispensable tools in ensuring that products meet the stringent requirements of safety and durability under varying temperatures. Whether for industrial use, research, or quality assurance, the right temperature chamber can provide significant insights into product behavior under extreme conditions and help in refining product designs. With this guide, you are equipped to make an informed decision on the best temperature chamber that suits your business needs, ensuring ongoing compliance and product excellence. Our temperature chambers

-

Climatic chamberClimatic chambers, essential in a multitude of industries, offer a controlled environment to simulate a range of atmospheric conditions. These devices are crucial for testing the reliability and durability of products under various environmental stresses. Whether you're involved in electronics, automotive, aerospace, or biotechnology, understanding climatic chambers can significantly impact your quality assurance processes. This guide provides an in-depth look at climatic chambers, their applications, and tips for selecting the ideal unit for your needs. What are Climatic Chambers? Climatic chambers, also known as environmental chambers, are specialized enclosures designed to replicate environmental conditions. They can adjust temperature, humidity, and other atmospheric parameters to precise levels, allowing researchers and engineers to observe how products and materials behave under different climatic scenarios. Applications of Climatic Chambers: Product Testing and Development: Simulating different climates to test product endurance and operation. Research and Innovation: Providing researchers the environment to study environmental effects on materials and biological entities. Quality Assurance: Ensuring products meet environmental compliance and withstand intended use conditions. Life Testing: Accelerating aging processes to predict product lifespan under normal and extreme conditions. Benefits of Climatic Chambers: Versatility: Suitable for a variety of industries and applications, from electronics to pharmaceuticals. Precision Control: Advanced technology to accurately simulate a wide range of environmental conditions. Consistency: Offers a consistent testing environment for reliable data and results. Compliance Support: Helps manufacturers meet strict regulatory standards by proving product robustness. Choosing the Right Climatic Chamber: When selecting a climatic chamber, consider these essential factors: Range of Conditions: Determine the temperature, humidity, and other environmental parameters needed for your tests. Size and Capacity: Match the chamber size to your product dimensions and the scale of your testing operations. Control Systems: Opt for chambers with user-friendly interfaces and precise control mechanisms. Energy Efficiency: Consider energy consumption, as climatic chambers can be significant power users. Maintenance and Support: Ensure availability of excellent customer service and technical support for maintenance. Conclusion: Climatic chambers are pivotal in ensuring that products can withstand the environmental conditions they will face in their lifetime. Whether enhancing product durability, conducting regulatory compliance testing, or performing research, the right climatic chamber is a valuable investment. By carefully evaluating your specific needs and the capabilities of different climatic chambers, you can choose a model that not only meets your requirements but also enhances your testing and development processes. Our climatic chambers

-

Battery testingBattery testing refers to the process of evaluating and analyzing the performance, characteristics, and safety of batteries under various conditions. This testing is essential to ensure that batteries meet specific standards, function reliably, and perform as expected in various applications, ranging from consumer electronics to electric vehicles and renewable energy storage systems. Battery testing involves a variety of measurements, assessments, and experiments to gather data about a battery's behavior and characteristics. Here are some key aspects of battery testing: 1. Performance testing: this involves evaluating a battery's capacity (the amount of energy it can store), energy efficiency (how effectively it converts stored energy into usable power), and discharge rates (how quickly it releases stored energy). 2. Cycle life testing: this assesses how many charge and discharge cycles a battery can undergo before its capacity significantly degrades. This is crucial for determining a battery's lifespan. 3. Environmental testing: batteries are often exposed to varying environmental conditions. Testing may involve subjecting batteries to extreme temperatures, humidity, and vibrations to assess how they perform and degrade under these conditions. 4. Safety testing: Safety is a critical concern, especially with lithium-ion batteries. Safety tests involve evaluating a battery's thermal stability, sensitivity to impact, short-circuit behavior, and potential for thermal runaway (a condition where a battery overheats and possibly catches fire). 5. Aging and shelf life testing: this assesses how a battery's performance changes over time, both during usage and when stored without being used. Shelf life testing determines how long a battery can be stored and still provide adequate performance. 6. Charge and discharge testing: this involves charging a battery to its full capacity and then discharging it under controlled conditions while measuring its voltage, current, and capacity. These tests help understand the battery's efficiency and characteristics. 7. Rate capability testing: This measures a battery's ability to deliver power quickly, which is important in applications like electric vehicles that require bursts of power for acceleration. 8. State of Charge (SOC) and State of Health (SOH) Monitoring: these tests assess the battery's current capacity and overall health. Knowing the SOC and SOH is critical for determining a battery's operational readiness. 9. Cycling and aging tests: Batteries are often cycled through different charge and discharge cycles to simulate real-world usage patterns and understand their long-term performance. 10. Emission and compatibility testing: Some battery chemistries might emit gases or substances when they degrade or fail. Emission and compatibility testing assesses potential hazards and interactions. 11. Electrical and thermal characterization: In-depth analysis of a battery's electrical properties and thermal behavior provides insights into its performance and safety. Battery testing is conducted in controlled environments using specialized testing equipment and protocols. The data collected from these tests informs manufacturers, researchers, and engineers about the battery's capabilities, limitations, and potential improvements. This knowledge is critical for designing safe, efficient, and reliable battery-powered products across a wide range of industries. Our climatic chambers

-

Battery test chamberThe Essential Guide to Battery Test Chambers: Applications, Advantages, and Selection Criteria Introduction: In the rapidly advancing world of technology, battery test chambers play a critical role in ensuring the safety, performance, and longevity of batteries across various applications. As industries like automotive, aerospace, and consumer electronics increasingly rely on battery power, understanding and utilizing battery test chambers becomes pivotal. This guide delves into the specifics of battery test chambers, their uses, benefits, and tips for choosing the right chamber to meet your testing needs. What are Battery Test Chambers? Battery test chambers are specialized environments designed to test the safety and performance of batteries under extreme conditions. These chambers simulate a variety of environmental factors including temperature, humidity, and altitude which are crucial for assessing battery reliability during normal and extreme use. Applications of Battery Test Chambers: Electric Vehicle (EV) Development: Ensuring EV batteries can withstand extreme conditions and meet longevity expectations.Consumer Electronics: Testing batteries in laptops, smartphones, and other portable devices to ensure safety and efficiency.Aerospace: Evaluating battery performance in high-altitude and varying temperature conditions.Renewable Energy Systems: Testing storage batteries used in solar and wind energy systems for reliability and safety. Benefits of Battery Test Chambers: Enhanced Safety: Identifying potential failures and hazards before batteries reach the market.Performance Verification: Assessing whether batteries can maintain their capacity and performance under various environmental stresses.Compliance and Certification: Helping manufacturers meet international safety and quality standards.Product Development: Facilitating the development of more robust and efficient batteries. Choosing the Right Battery Test Chamber: Selecting an appropriate battery test chamber involves several key considerations: Testing Requirements: Determine the specific environmental conditions needed to test your batteries, such as temperature range and humidity levels.Battery Size and Quantity: Consider the chamber size that can accommodate the number and size of batteries you plan to test.Customization Options: Look for chambers that offer adjustable settings and features that match your specific testing needs.Safety Features: Ensure the chamber includes safety mechanisms like explosion-proof interiors and emergency shutoffs.Budget and Operational Costs: Balance the initial investment with the ongoing operational costs, including energy consumption and maintenance.Conclusion: Battery test chambers are invaluable tools in the battery manufacturing and research sectors, providing insights into battery behavior under diverse environmental conditions. By selecting a suitable battery test chamber, companies can not only enhance the safety and performance of their products but also adhere to global standards, thereby boosting consumer confidence and product reliability. Whether for small-scale testing or large-volume production, understanding and investing in the right battery test chamber is essential for any organization focused on cutting-edge battery technology and innovation. Our climatic chambers