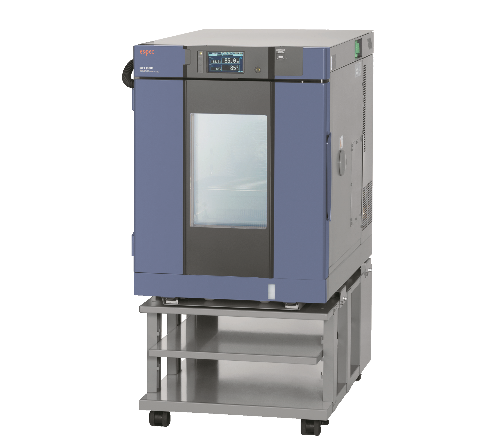

Espec Vacuum Ovens

Description:

If the ambient pressure is low, test samples will already dry at a lower temperature. This enables rapid and safe drying of heat-sensitive products. The low ambient pressure also ensures that the boiling point is a lot lower, causing less stress on a product.

The Espec vacuum ovens are often used for applications in the chemical, aviation, food, cosmetics and pharmaceutical industries. The vacuum models are available in 91, 216 and 512-litre versions. Furthermore, all models feature a user-friendly LCD touch panel controller on the oven front which can be used to control, monitor and program the vacuum oven. Remote communication with the oven via GPIB, RS-232c or RS-485 is also possible.

Technical specifications

- Capacity:

Temperature range:

Temperature fluctuation:

Air pressure range:

Controller:

Logging:

Viewing window:

- 91, 216 or 512 litre

+40°C to +200°C

± 0,5°C (± 1,0°C at atmospheric pressure)

933×10² to 1×10² Pa

Touchscreen program controller

USB (option)

Viewing window in door (option)

Benefits:

- • User friendly touchscreen controller

• Uniform temperature distribution

• Mobile installation (casters and leveling feet)

• Advanced programming mode

• Rapid heating

Some options:

- • Viewing window in door

• Hermetic connections for thermocouples

• Alarm terminals

• USB logging

• Reinforced floor for heavy products

Industries:

- • Automotive

• Aerospace

• Chemistry

• Cosmetics

• Electronics

• Energy

• Food

• Packaging

• Pharma / medical

• Semiconductor

Applications:

- • Temperature tests

• Drying (vacuum)

• Heat treatment

• Curing

• Laboratories

Related Products

-

ETERNAL SUN AND SOLLIANCE PARTNERS DEVELOP UNIQUE SOLAR TESTING SYSTEMA Dutch consortium, consisting of Eternal Sun, Hielkema Testequipment, Rera Solutions and Solliance partners ECN and TNO will develop a climate chamber with AAA-class accuracy simulated sunlight to simultaneously test performance and degradation of all types of solar cells and mini-modules. This unique combination is able to gather information which is at the moment unattainable. The equipment is expected to become commercially available in the first half of 2015.

ETERNAL SUN AND SOLLIANCE PARTNERS DEVELOP UNIQUE SOLAR TESTING SYSTEMA Dutch consortium, consisting of Eternal Sun, Hielkema Testequipment, Rera Solutions and Solliance partners ECN and TNO will develop a climate chamber with AAA-class accuracy simulated sunlight to simultaneously test performance and degradation of all types of solar cells and mini-modules. This unique combination is able to gather information which is at the moment unattainable. The equipment is expected to become commercially available in the first half of 2015. -

22ND ESPEC CHAMBER IN 22 YEARS OF SUCCESSFUL BUSINESSAbout 22 years ago (1993), Kees Revenberg, director of MASER Engineering BV, bought the first Espec climate test system from Peter Hielkema, former director of Hielkema Testequipment BV. Now, after 22 years of successful business cooperation, MASER Engineering BV has expanded their wide range of Espec test systems with yet another Espec test system

22ND ESPEC CHAMBER IN 22 YEARS OF SUCCESSFUL BUSINESSAbout 22 years ago (1993), Kees Revenberg, director of MASER Engineering BV, bought the first Espec climate test system from Peter Hielkema, former director of Hielkema Testequipment BV. Now, after 22 years of successful business cooperation, MASER Engineering BV has expanded their wide range of Espec test systems with yet another Espec test system -

CLIMATE CHAMBER WITH SOLAR SIMULATORAbout 4 years ago, Hielkema Testequipment, Eternal Sun & TNO developed a unique solar testing system for Solliance (High Tech Campus in Eindhoven). This system has been used very successfully to gain new insights into the degradation behavior of solar cells and mini-modules.

CLIMATE CHAMBER WITH SOLAR SIMULATORAbout 4 years ago, Hielkema Testequipment, Eternal Sun & TNO developed a unique solar testing system for Solliance (High Tech Campus in Eindhoven). This system has been used very successfully to gain new insights into the degradation behavior of solar cells and mini-modules. -

TÜV SÜD AND ESPEC PARTNERING FOR ELECTRIC VEHICLE BATTERY TESTING IN JAPAN.TÜV SÜD and ESPEC are currently expanding ESPEC's existing battery laboratory in Japan. By partnering up, the main aim is to offer a complete range of tests for drive batteries of electric cars. This will become the seventh lab of TÜV SÜD in the international network of battery labs.

TÜV SÜD AND ESPEC PARTNERING FOR ELECTRIC VEHICLE BATTERY TESTING IN JAPAN.TÜV SÜD and ESPEC are currently expanding ESPEC's existing battery laboratory in Japan. By partnering up, the main aim is to offer a complete range of tests for drive batteries of electric cars. This will become the seventh lab of TÜV SÜD in the international network of battery labs. -

TESTING OF LITHIUM-ION BATTERIES FOR ENERGY STORAGE SYSTEMS.The effective storage of energy is a development that receives a lot of attention from different sectors. The market for energy storage systems (including lithium-ion batteries) is currently growing explosively and offers many opportunities for various applications.

TESTING OF LITHIUM-ION BATTERIES FOR ENERGY STORAGE SYSTEMS.The effective storage of energy is a development that receives a lot of attention from different sectors. The market for energy storage systems (including lithium-ion batteries) is currently growing explosively and offers many opportunities for various applications. -

LV 124 AUTOMOTIVE TEST STANDARDSince 2010 the LV 124 has become the most important test standard for the automotive industry. The LV 124 includes several mechanical, climatic and life tests, such as the K-09 damp heat cyclic test, the K-15 condensation test and the L-03 temperature cycle life test.

LV 124 AUTOMOTIVE TEST STANDARDSince 2010 the LV 124 has become the most important test standard for the automotive industry. The LV 124 includes several mechanical, climatic and life tests, such as the K-09 damp heat cyclic test, the K-15 condensation test and the L-03 temperature cycle life test. -

Test facilityOur brand new test facility offers the possibility to see and test our products, but makes it also available for individual pre-compliance testing. In our test facility we have several climatic chambers, one salt spray chamber and 3 large walk-in climatic chambers available for testing.

Test facilityOur brand new test facility offers the possibility to see and test our products, but makes it also available for individual pre-compliance testing. In our test facility we have several climatic chambers, one salt spray chamber and 3 large walk-in climatic chambers available for testing.